Common Pipe Installation Techniques

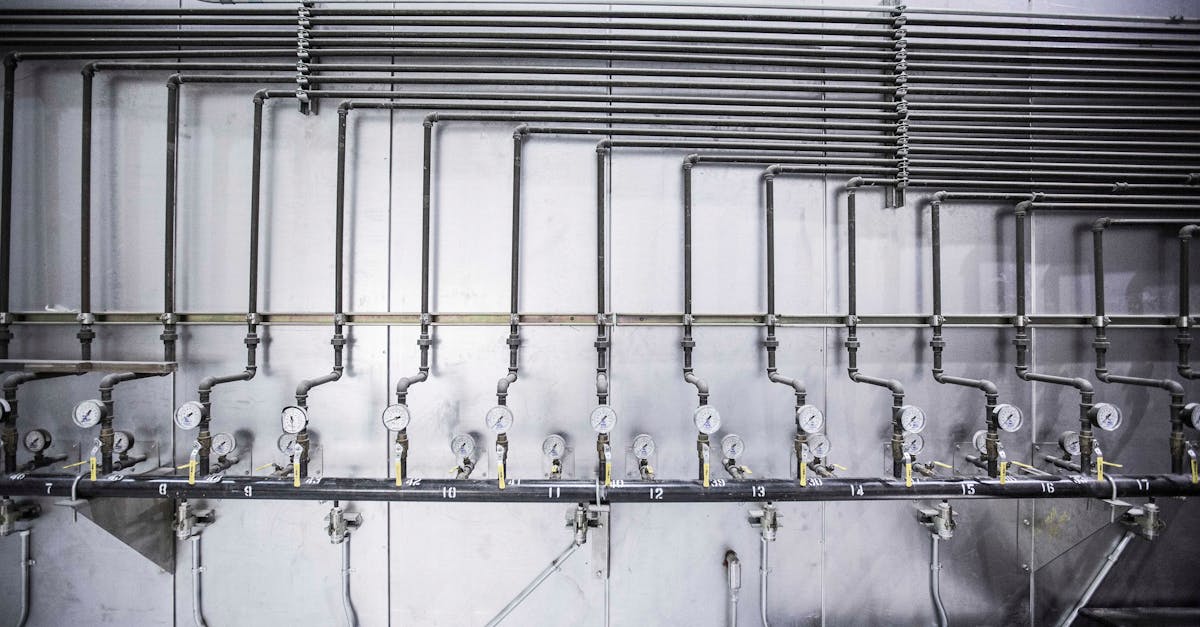

Common pipe installation techniques involve several methods that enhance the effectiveness and efficiency of the process. One widely used technique is the use of PVC piping, favored for its lightweight and corrosion-resistant properties. This material is easily assembled with solvent cement, making it ideal for residential plumbing. For larger systems, techniques such as welding or soldering are common, especially when working with metal pipes. These methods create strong, permanent joints that handle high-pressure situations effectively.

In regions like West Liberty, Pittsburgh, plumbers often rely on these techniques to ensure safe and reliable installations. Selecting the right method depends on the specific requirements of the project, including pipe materials and the intended application. Professionals in this field must stay updated with the latest practices and technologies to deliver quality work while adhering to local regulations. Proper technique not only ensures durability but also contributes to the overall efficiency of plumbing systems in both residential and commercial settings.

Methods of Joining Pipes

Several methods exist for joining pipes, each suited for specific applications and materials. For instance, welded joints are commonly used in metal piping systems, providing strong, permanent connections. Other techniques include threaded joints, which offer the flexibility to disassemble and reassemble pipes as necessary, and solvent welding, often used with plastic pipes, creating a secure bond by chemically melting the surfaces together.

In the context of pipe installation and repair in West Liberty, Pittsburgh, it's vital to choose an appropriate joining method based on factors like the environment, type of fluid being transported, and local building codes. Additionally, understanding the advantages and limitations of each method can enhance the longevity and efficiency of the pipe system, ensuring that it meets the specific needs of the installation while adhering to safety regulations.

Safety Precautions for Pipe Installation

Safety is paramount when engaging in pipe installation and repair in West Liberty, Pittsburgh. Proper personal protective equipment (PPE) should always be worn. This includes hard hats, gloves, eye protection, and steel-toed boots. Workers must be familiar with the specific hazards associated with the task, especially when working with heavy materials or in cramped spaces. Ensuring that the work area is well-ventilated helps prevent inhalation of harmful fumes, particularly when soldering or using adhesives.

Additionally, it's crucial to maintain awareness of one’s surroundings and the tools in use. Keeping work areas clutter-free minimizes the risk of accidents. Regular inspections of equipment can prevent malfunctions that could lead to injuries. Before beginning any project, completing a thorough risk assessment allows workers to identify potential hazards and implement necessary controls. By adhering to these safety measures, the likelihood of accidents during pipe installation and repair can be significantly reduced.

Best Practices to Prevent Accidents

Ensuring safety during pipe installation requires adherence to best practices that minimize the risk of accidents. Workers should consistently wear appropriate personal protective equipment, including hard hats, gloves, and safety goggles. Additionally, the work area must be kept clear of debris and hazards that could lead to trips or falls. Regular safety training sessions increase awareness of potential hazards and reinforce the importance of following safety protocols.

During pipe installation and repair in West Liberty, Pittsburgh, it is essential to conduct thorough inspections of tools and equipment before use. Identifying any defects or malfunctions beforehand minimizes the likelihood of accidents. It is also vital to ensure that all team members are well-informed about their roles and responsibilities, promoting effective communication. Proper planning and risk assessments can help in anticipating challenges, further enhancing the safety of the installation process.

Career Opportunities in Pipe Installation

The field of pipe installation offers various career opportunities, appealing to those with diverse skill sets. Many positions require specialized training and knowledge of plumbing systems, which can often be acquired through vocational schools or apprenticeships. Experienced plumbers and pipefitters may take on more advanced roles, including project management or system design. The demand for skilled professionals continues to grow as infrastructure development increases, especially in urban areas.

In locations like West Liberty, Pittsburgh, the need for proficient pipe installers remains consistent. This growing market presents a favorable job outlook for individuals entering the profession. With the continuous evolution of building codes and technology, ongoing training is beneficial for career advancement. Those interested in pipe installation can find a range of opportunities in residential construction, commercial projects, and industrial applications.

Job Market Trends and Demand

The job market for pipe installation and repair has seen steady growth in recent years. With increasing infrastructure projects across the country, skilled workers are in high demand. Factors such as population growth and urban development have led to a need for efficient piping systems in both residential and commercial properties. This trend is particularly noticeable in regions like West Liberty, Pittsburgh, where ongoing construction contributes to a higher demand for experienced pipe installers.

Additionally, advancements in technology and methods within the plumbing industry are creating new job opportunities. As modern techniques continue to evolve, training and expertise in contemporary practices become essential. The emphasis on sustainable plumbing solutions has further stimulated the market, attracting environmentally conscious initiatives. This dynamic environment provides various pathways for those pursuing a career in pipe installation and repair, especially in areas experiencing significant growth.

FAQS

What do you call someone who installs pipes?

Someone who installs pipes is typically referred to as a plumber.

What are the main responsibilities of a plumber?

A plumber's main responsibilities include installing, repairing, and maintaining piping systems for water, gas, and drainage.

What qualifications do I need to become a plumber?

To become a plumber, you usually need a high school diploma or equivalent, completion of an apprenticeship program, and a valid plumbing license, which varies by state.

What are the common pipe installation techniques?

Common pipe installation techniques include soldering, threading, and using mechanical fittings to join pipes together.

Is plumbing a stable career choice?

Yes, plumbing is considered a stable career choice, with consistent demand for skilled plumbers due to ongoing construction and maintenance needs.